- +8613859957860

- [email protected]

- No.11 Shuangfu Road, Tong’an District, Xiamen, China

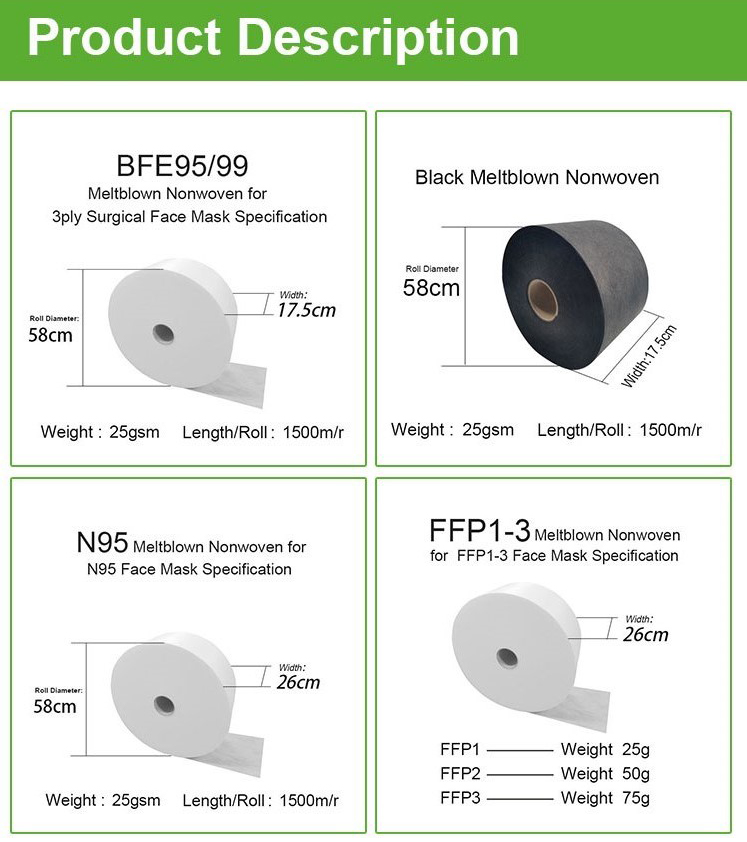

Raw Material | 100% polypropylene |

Width | 175mm, 260mm or customized |

Weight(GSM) | 25gsm, 50gsm or customized |

Packing | Packed in roll and protected by film |

BFE | 99%~100% |

PFE | 95%~99% |

MOQ | 1000kg |

Our Capacity | 10 tons per day |

Meltblown nonwoven fabric made from 100% polypropylene (PP) is an essential material in the medical field, especially for products like face masks, surgical gowns, and filtration systems. Here’s a detailed overview of its properties, uses, and benefits.

1. High Filtration Efficiency: Meltblown PP nonwoven fabric is known for its superior filtration capabilities. It can achieve BFE (Bacterial Filtration Efficiency) and PFE (Particle Filtration Efficiency) ratings of up to 99%, making it highly effective at blocking airborne particles and pathogens.

2. Ultra-Fine Fibers: The fabric is composed of ultra-fine fibers with diameters around 2 microns. This fine structure enhances its filtration efficiency while maintaining breathability.

3. Breathability and Water Resistance: Due to its unique structure, meltblown nonwoven fabric is both breathable and water-resistant. This dual property is critical for medical applications where maintaining a barrier against fluids without compromising airflow is necessary.

4. Lightweight and Soft: The fabric is lightweight and soft, ensuring comfort when used in products like face masks and medical gowns.

Medical Masks: The primary use of meltblown nonwoven fabric is in medical masks. It forms the critical middle layer in surgical masks and respirators, providing essential filtration to protect against bacteria and viruses.

Surgical Gowns and Drapes: Its ability to act as a barrier against fluids makes it ideal for surgical gowns and drapes, ensuring that healthcare professionals are protected during procedures.

Filtration Systems: Beyond medical use, meltblown fabric is used in air and liquid filtration systems, including HVAC filters and water filters, due to its high efficiency in trapping particulate matter.

Environmental Applications: Its high absorbency makes it suitable for use in oil spill cleanups and other environmental protection applications where large amounts of liquid need to be absorbed quickly.

Manufacturers of meltblown nonwoven fabric implement stringent quality control measures to ensure the fabric meets high standards of efficiency and safety. Facilities are often ISO certified and conduct thorough testing to maintain consistency and reliability in their products.

The demand for high-quality meltblown nonwoven fabric has surged, particularly during health crises like the COVID-19 pandemic. Suppliers typically offer customizable options regarding weight (ranging from 10gsm to 50gsm), width, and color to meet specific requirements.

In conclusion, 100% polypropylene meltblown nonwoven fabric is a crucial material in the medical industry, offering high filtration efficiency, comfort, and versatility. Its application in protective equipment and filtration systems underscores its importance in safeguarding health and enhancing safety standards.

Our robust production capacity and dedicated R&D team are geared towards saving your time, allowing you to seize the selling season. With six production lines dedicated to P.P. nonwoven fabric, our monthly output reaches an impressive 1300 tons.

Our sales team is well-versed in international trade, regularly participating in numerous domestic and international trade shows. Additionally, we leverage various online networking platforms to expand our presence and reach in the global market.

Ensuring a steady supply of raw materials, we commit to offering consistently stable pricing. This practice not only guarantees the mutual benefit of both parties involved but also serves as a risk-mitigation strategy in the dynamic landscape of nonwoven fabric trade. Our focus on securing ample raw material reserves empowers us to maintain pricing stability, fostering a reliable and enduring partnership that prioritizes mutual success and minimizes uncertainties associated with trade in this industry.

We boast a comprehensive quality management system alongside highly competitive pricing. Over 95% of our products, tailored to diverse fields, are exported to 30+ countries, meeting their specific requirements. Additionally, we have forged strong business partnerships with renowned global brands.

The OEKO-TEX® Standard 100 is an autonomous testing and certification protocol that covers textile raw materials, intermediates, and final products throughout their production stages. It encompasses various items eligible for certification, including clothing of all kinds, household textiles, bed linens, terry cloth items, textile toys, and more.

Find the more non-woven fabrics from our factory with free custom services at cheapest price.