- +8613859957860

- [email protected]

- No.11 Shuangfu Road, Tong’an District, Xiamen, China

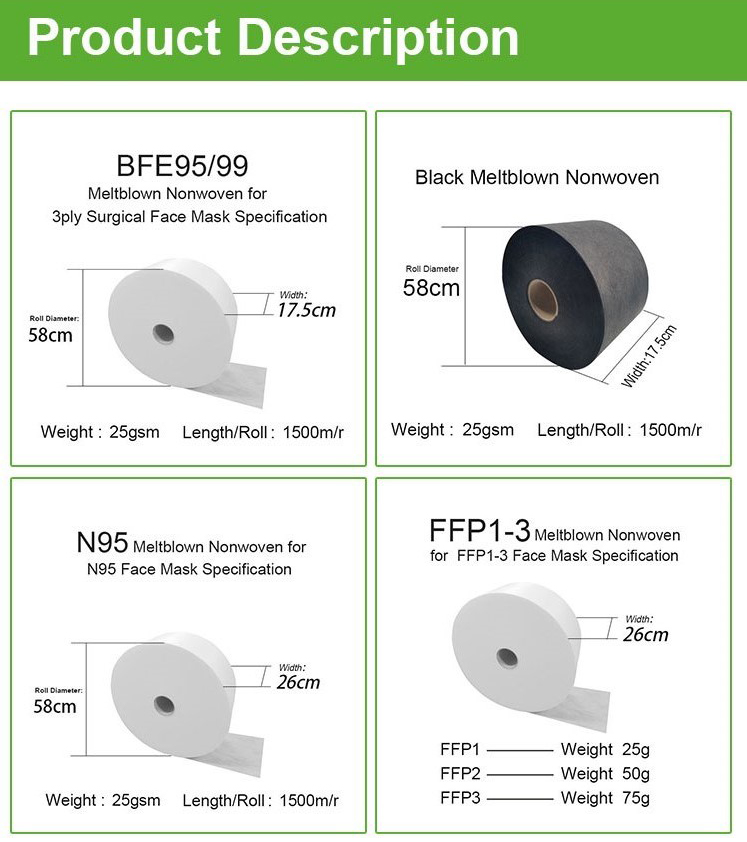

Raw Material | 100% polypropylene |

Width | 175mm, 260mm or customized |

Weight(GSM) | 25gsm, 50gsm or customized |

Packing | Packed in roll and protected by film |

BFE | 99%~100% |

PFE | 95%~99% |

MOQ | 1000kg |

Our Capacity | 10 tons per day |

In the rapidly evolving landscape of personal protective equipment (PPE), the quality and efficiency of materials are critical. The 25 GSM 175mm BFE99 meltblown nonwoven fabric is a cornerstone of disposable mask production, offering exceptional filtration efficiency, comfort, and adaptability for various applications.

High Filtration Efficiency: The BFE99 rating indicates that this fabric filters out 99% of airborne particles. This makes it an excellent choice for masks intended to protect against bacteria, viruses, and other harmful particulates.

Lightweight and Comfortable: At just 25 GSM, the fabric is extremely lightweight, ensuring that masks are comfortable for extended wear without causing significant discomfort or breathing difficulties.

Optimal Width for Mask Production: With a width of 175mm, the fabric is ideally suited for the production of standard disposable masks. This dimension supports efficient manufacturing processes, reducing material waste and ensuring consistent mask quality.

Breathability and Low Resistance: Despite its high filtration capability, the meltblown fabric maintains excellent breathability. This balance is crucial for ensuring that masks are both effective and comfortable, allowing for easy airflow with minimal resistance.

Versatile Applications: Beyond disposable masks, this meltblown fabric is suitable for various applications requiring high filtration efficiency, such as air filters and medical garments.

Enhanced Durability: The fabric’s structure ensures long-term durability, making it reliable for consistent use in various environmental conditions.

Cost-Effective Production: The lightweight nature and standardized width of the fabric allow for cost-effective production processes, making it a viable option for large-scale manufacturing without compromising on quality.

Environmental Sustainability: The efficiency of the material and the reduction in waste during production contribute to more sustainable manufacturing practices, aligning with the increasing focus on environmental responsibility.

3-Ply Disposable Masks: This fabric is a key component in the middle layer of 3-ply masks, providing essential filtration while maintaining breathability.

KN95 Masks: The fabric’s high filtration efficiency makes it ideal for KN95 masks, which require stringent protective standards.

N95 and N99 Respirators: Used in N95 and N99 masks, the fabric offers superior protection against airborne particles, meeting regulatory requirements for medical and industrial use.

Air Filter Fabric: Its high filtration efficiency and breathability make it suitable for use in air filters, enhancing indoor air quality in various environments.

Medical Garments: The fabric is also used in the production of medical gowns and other protective clothing, providing an additional layer of protection for healthcare workers.

Enhanced Protection: Masks made from this material offer robust protection against pathogens, making them suitable for medical and healthcare settings.

Economic Efficiency: Its lightweight nature and optimal width allow for cost-effective production, reducing overall manufacturing costs.

Environmental Considerations: Sustainable manufacturing practices are supported by the fabric’s efficiency and minimal waste production.

The 25 GSM 175mm BFE99 meltblown nonwoven fabric is an essential material in the production of high-quality disposable masks. Its combination of high filtration efficiency, lightweight properties, and breathability makes it ideal for ensuring user safety and comfort. As the demand for reliable protective gear continues to grow, this meltblown fabric will remain a critical component in healthcare and various other industries.

Our robust production capacity and dedicated R&D team are geared towards saving your time, allowing you to seize the selling season. With six production lines dedicated to P.P. nonwoven fabric, our monthly output reaches an impressive 1300 tons.

Our sales team is well-versed in international trade, regularly participating in numerous domestic and international trade shows. Additionally, we leverage various online networking platforms to expand our presence and reach in the global market.

Ensuring a steady supply of raw materials, we commit to offering consistently stable pricing. This practice not only guarantees the mutual benefit of both parties involved but also serves as a risk-mitigation strategy in the dynamic landscape of nonwoven fabric trade. Our focus on securing ample raw material reserves empowers us to maintain pricing stability, fostering a reliable and enduring partnership that prioritizes mutual success and minimizes uncertainties associated with trade in this industry.

We boast a comprehensive quality management system alongside highly competitive pricing. Over 95% of our products, tailored to diverse fields, are exported to 30+ countries, meeting their specific requirements. Additionally, we have forged strong business partnerships with renowned global brands.

The OEKO-TEX® Standard 100 is an autonomous testing and certification protocol that covers textile raw materials, intermediates, and final products throughout their production stages. It encompasses various items eligible for certification, including clothing of all kinds, household textiles, bed linens, terry cloth items, textile toys, and more.

Find the more non-woven fabrics from our factory with free custom services at cheapest price.