- +8613859957860

- [email protected]

- No.11 Shuangfu Road, Tong’an District, Xiamen, China

Face masks have become an essential part of daily life, offering protection in healthcare, industrial, and public settings. But what goes into making these masks effective? The secret lies in the mask raw materials, including non-woven fabrics, meltblown layers, and other critical components. Understanding these materials helps industries innovate and consumers appreciate the science behind everyday essentials.

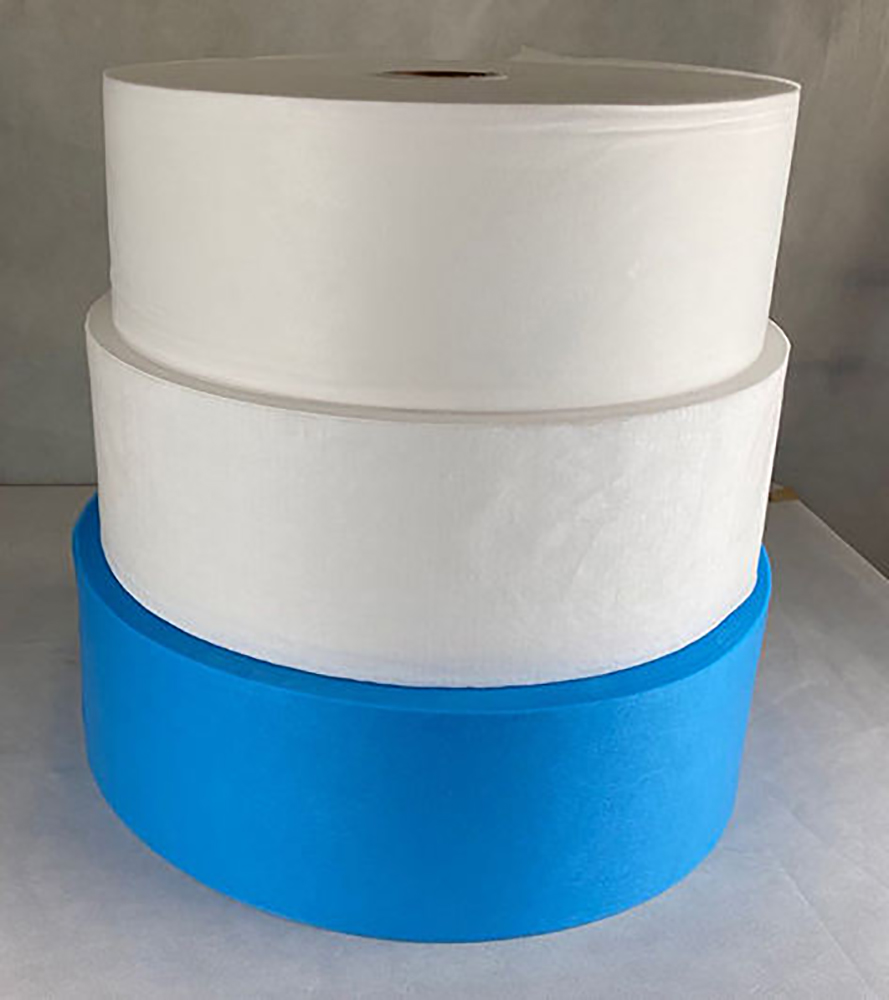

There are disposable face masks and industry respirators, such as 3ply face mask, medical masks, KN95 masks, KF94 masks, FFP2, FFP3 cup masks and respirators, the raw materials are meltblown fabric, nonwoven fabric, needle punched nonwoven, activated carbon nonwoven, nose wire, earloop, etc.

Mask raw materials are the building blocks of face masks, defining their effectiveness, comfort, and durability. From the outer layer to the filtration layer, every component plays a crucial role in meeting specific standards.

The careful selection and combination of these materials determine whether masks meet medical or industrial-grade requirements.

Non-woven fabrics are the backbone of face mask production. Unlike woven fabrics, they are created by bonding fibers through heat, pressure, or adhesives, resulting in a versatile and cost-effective material.

Nonwoven fabrics like spunbond and meltblown ensure masks meet the highest performance standards.

Meltblown fabric is the star of the show when it comes to filtration. Made from polypropylene, this ultra-fine fabric captures particles as small as 0.1 microns, making it ideal for medical masks.

Its electrostatic properties enhance filtration, making it indispensable in medical-grade masks.

Spunbond nonwoven fabric forms the outer and inner layers of most masks. Its lightweight yet durable nature makes it an ideal choice for these applications.

| Property | Benefit |

|---|---|

| Lightweight | Enhances user comfort. |

| Hydrophobic | Resists water and fluid penetration. |

| Cost-Effective | Reduces production costs for manufacturers. |

Together with meltblown fabric, spunbond ensures masks meet stringent safety and comfort standards.

Polypropylene (PP) is the primary material for most mask layers due to its versatility and performance. Polyester is sometimes blended to enhance certain properties.

High-quality mask materials share specific properties that make them effective for protection.

| Property | Impact |

|---|---|

| Filtration Efficiency | Captures particles like dust and microbes. |

| Breathability | Reduces discomfort for prolonged use. |

| Skin-Friendliness | Prevents irritation during wear. |

These properties ensure that masks meet user needs while adhering to regulatory standards.

Raw materials differ depending on the mask type:

Each mask type is tailored to specific use cases, from personal to industrial protection.

Quality assurance is critical in mask production to maintain safety and performance standards. Reliable suppliers:

Trustworthy suppliers ensure a steady supply of reliable raw materials.

The rise in mask usage has raised concerns about environmental impact. Manufacturers are addressing this by:

These efforts aim to balance public health needs with environmental responsibility.

The future of mask raw materials looks promising with innovations in materials science. Potential developments include:

The focus will remain on enhancing efficiency while addressing global challenges like sustainability and supply chain resilience.