- +8613859957860

- [email protected]

- No.11 Shuangfu Road, Tong’an District, Xiamen, China

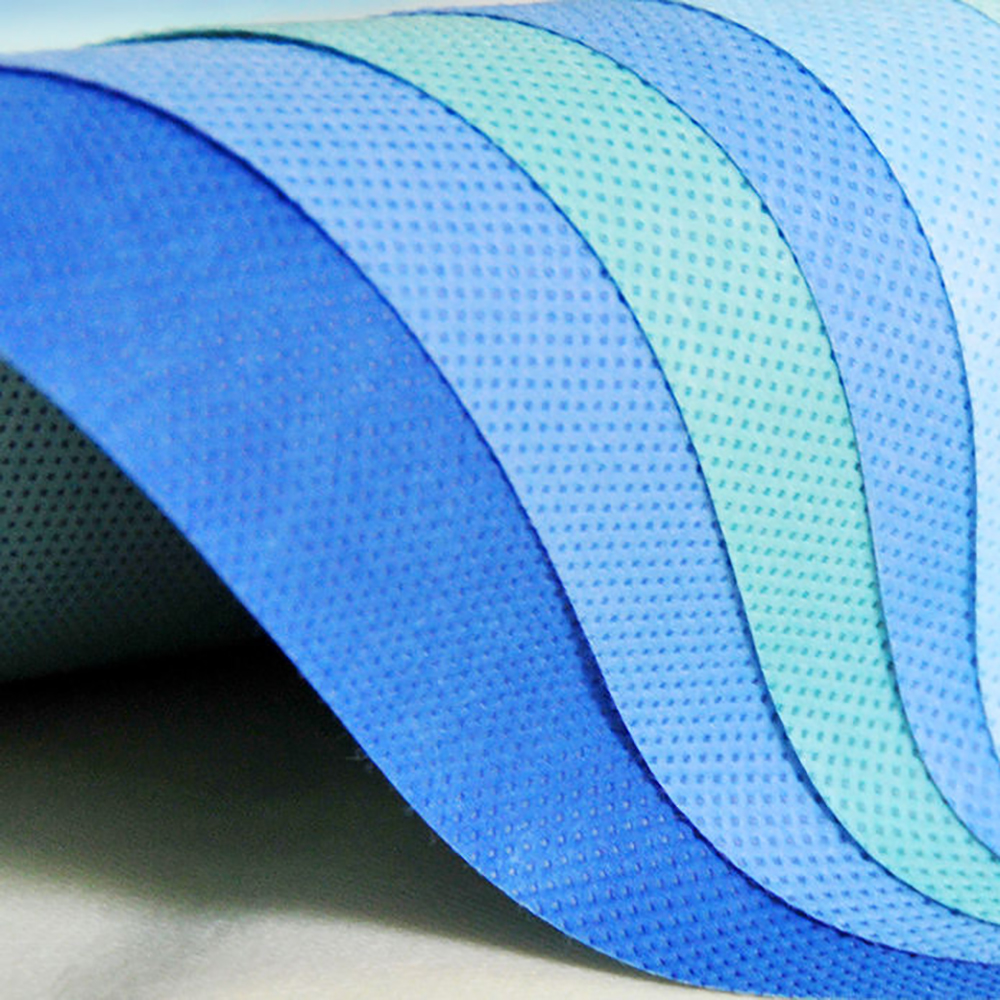

SMS nonwoven fabric has revolutionized industries with its exceptional versatility, durability, and affordability. From medical applications to hygiene products and industrial uses, SMS nonwoven fabric is at the heart of numerous essential products we use every day.

SMS nonwoven fabric technology is spun-melt, there are SMS, SMMS, SSMMS nonwoven fabric, it’s used for medical surgical gown, medical sheets, it’s also used for hygiene products, such as SPA bed sheets, leg cuff for baby diaper and cleaning wipes, industry wipes, etc.

SMS nonwoven fabric stands for Spunbond-Meltblown-Spunbond. It’s a tri-layer composite material composed of polypropylene that combines strength, softness, and excellent filtration properties.

This unique structure allows SMS nonwoven fabric to be used in applications requiring breathability, water resistance, and filtration.

The production of SMS fabric involves combining spunbond and meltblown processes in a seamless operation.

| Layer | Function |

|---|---|

| Spunbond | Strength and structure |

| Meltblown | Filtration and barrier |

| Spunbond | Comfort and durability |

This process ensures the material’s lightweight and multifunctional properties.

SMS nonwoven fabric boasts a range of desirable properties that make it indispensable.

These traits are particularly valuable in industries like healthcare and sanitation.

Medical-grade SMS nonwoven fabric is a cornerstone of protective and sanitary products. Its unique properties ensure safety and reliability in critical environments.

SMS fabric is preferred because it meets stringent hygiene standards while remaining cost-effective.

SMMS nonwoven fabric is an advanced version of SMS with additional layers for improved functionality.

| Property | SMS | SMMS |

|---|---|---|

| Layers | 3 (Spunbond-Meltblown-Spunbond) | 4 (Spunbond-Meltblown-Meltblown-Spunbond) |

| Filtration | Standard | Higher filtration efficiency |

| Applications | General | High-performance needs |

For industries requiring superior filtration, SMMS fabric offers an edge.

The meltblown polypropylene layer is the functional core of SMS fabric, contributing significantly to its filtration and barrier properties.

This middle layer is critical for applications like medical masks and air filters.

SMS nonwoven fabric finds application in a wide array of industries due to its adaptability and reliability.

Its versatility makes it a material of choice across sectors.

In hygiene and sanitation, SMS fabric plays a pivotal role by offering a combination of absorbency, filtration, and water resistance.

These properties make it indispensable in personal hygiene products like sanitary pads and adult diapers.

While SMS fabric provides numerous benefits, its polypropylene base raises environmental concerns. However, innovations are addressing these challenges.

Sustainability is becoming a focus area for manufacturers.

The future of SMS nonwoven fabric is bright, with ongoing advancements poised to expand its applications.

These innovations will ensure SMS fabric remains relevant in an evolving market.