- +8613859957860

- [email protected]

- No.11 Shuangfu Road, Tong’an District, Xiamen, China

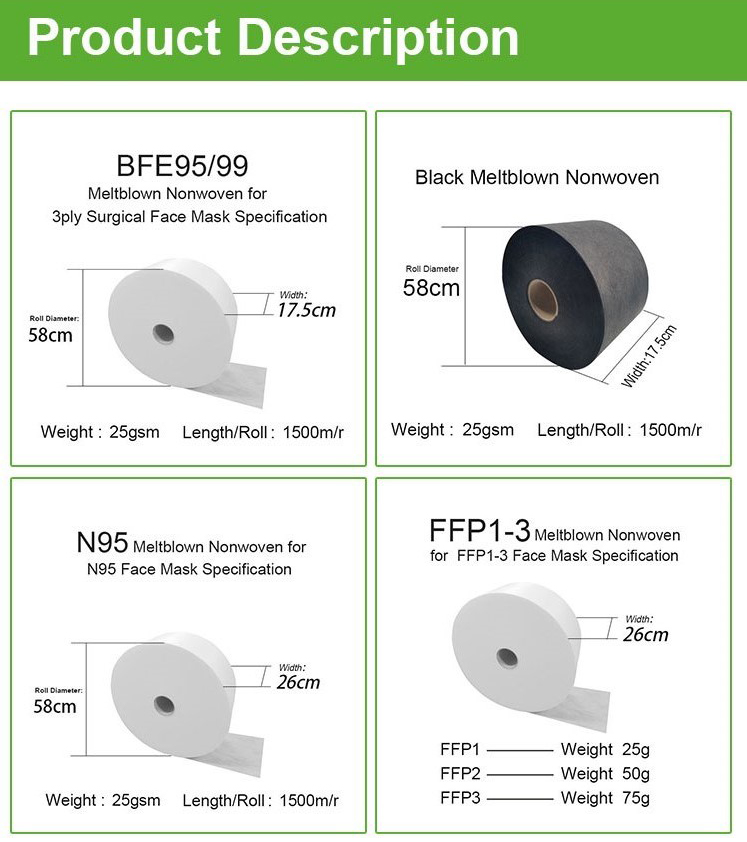

| Meltblown fabric specification | |

| Weight | 25gsm |

| Bacterial Filtration Efficiency (BFE) % | ≥99% |

| Particulate Filtration Efficiency(PFE) % | ≥99% |

| Differential Pressure,mm H20/CM2,Breathability | ≤5.0 |

| Resistance to Penetration by Synthetic Blood, mmHg | ≥160 |

| Microbial Cleanliness (cfu/g) | ≤30 |

| Flame Spread | Class 1 |

| Test Standards | |

| EN14683-2019 TYPE IIR, ASTM F2100-2019 L3, YY0469 | |

Meltblown nonwoven fabric stands as a pinnacle of innovation in filtration technology, offering unparalleled efficiency and versatility. This article explores the unique characteristics of high filter efficiency meltblown nonwoven fabric and its essential role in the production of respirators and other protective gear.

Meltblown nonwovens are highly effective in capturing and filtering particles due to their unique fiber structure. The fine fibers create a dense and intricate network that can efficiently trap even the smallest particles. This makes meltblown fabric an ideal choice for air and liquid filtration applications, where precision and reliability are paramount.

High Filtration Efficiency: The fine fibers of meltblown nonwovens form a dense matrix that can capture particles down to the micron level. This makes them suitable for critical filtration applications, including air and liquid filters.

Excellent Barrier Properties: The dense structure of meltblown nonwoven fabric provides excellent barrier properties, preventing the penetration of liquids, microorganisms, and other contaminants. This makes it ideal for use in protective apparel, surgical masks, and other barrier applications.

Breathability: Despite their high filtration efficiency, meltblown nonwovens maintain good breathability. The fine fibers allow for air passage, making the material comfortable to wear. This is particularly important for applications like face masks and respirators, where both protection and comfort are essential.

Absorbent Properties: Meltblown nonwovens exhibit good absorbent properties. The fine fibers can quickly absorb liquids, making them useful in absorbent pads, wipes, and filtration media for oil filter elements.

Versatility: Meltblown nonwovens can be produced with varying fiber sizes, densities, and compositions, allowing them to meet specific requirements across various industries. They can be combined with other materials or used as standalone products, offering flexibility in design and performance.

We produce the highest quality meltblown nonwoven fabrics, ensuring that our products are efficient, durable, and feature a large inner surface area that supports mechanical deposition effects. This makes them perfect for a wide range of applications, including air and liquid filter media, acoustics, food and beverage filtration, face masks and respirators, wound care, and even stretchable and elastic textile applications.

Our PP (polypropylene) meltblown fabric is composed of fine fibers ranging from 1 to 5 microns (μm), providing excellent filtration performance as a core media in many filtration systems. This includes FFP2 melt blown and FFP3 meltblown fabric for respirators.

High filter efficiency meltblown nonwoven fabric is indispensable in the production of respirators and other protective equipment. Its unique combination of high filtration efficiency, excellent barrier properties, breathability, and versatility ensures that it meets the stringent demands of various industries. Our commitment to producing the highest quality meltblown nonwoven fabrics guarantees that our products deliver superior performance, durability, and reliability in every application.

Our robust production capacity and dedicated R&D team are geared towards saving your time, allowing you to seize the selling season. With six production lines dedicated to P.P. nonwoven fabric, our monthly output reaches an impressive 1300 tons.

Our sales team is well-versed in international trade, regularly participating in numerous domestic and international trade shows. Additionally, we leverage various online networking platforms to expand our presence and reach in the global market.

Ensuring a steady supply of raw materials, we commit to offering consistently stable pricing. This practice not only guarantees the mutual benefit of both parties involved but also serves as a risk-mitigation strategy in the dynamic landscape of nonwoven fabric trade. Our focus on securing ample raw material reserves empowers us to maintain pricing stability, fostering a reliable and enduring partnership that prioritizes mutual success and minimizes uncertainties associated with trade in this industry.

We boast a comprehensive quality management system alongside highly competitive pricing. Over 95% of our products, tailored to diverse fields, are exported to 30+ countries, meeting their specific requirements. Additionally, we have forged strong business partnerships with renowned global brands.

The OEKO-TEX® Standard 100 is an autonomous testing and certification protocol that covers textile raw materials, intermediates, and final products throughout their production stages. It encompasses various items eligible for certification, including clothing of all kinds, household textiles, bed linens, terry cloth items, textile toys, and more.

Find the more non-woven fabrics from our factory with free custom services at cheapest price.