- +8613859957860

- [email protected]

- No.11 Shuangfu Road, Tong’an District, Xiamen, China

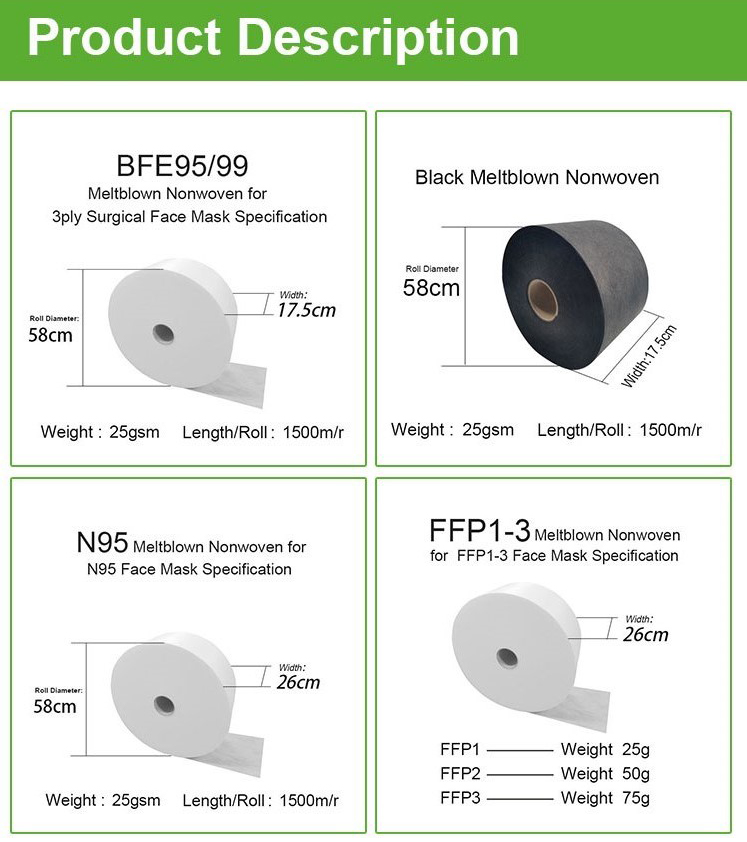

Raw Material | 100% polypropylene |

Width | 175mm, 260mm or customized |

Weight(GSM) | 25gsm, 50gsm or customized |

Packing | Packed in roll and protected by film |

BFE | 99%~100% |

PFE | 95%~99% |

MOQ | 1000kg |

Our Capacity | 10 tons per day |

Introduction

Melt blown nonwoven fabric has become an integral material in various industries, especially in medical applications. Its unique properties make it ideal for producing high-efficiency filtration materials. This article will delve into the characteristics, production process, and applications of medical BFE99 melt blown nonwoven fabric rolls, highlighting their critical importance in ensuring public health and safety.

1. Microfiber Diameter and Distribution: Melt blown nonwoven fabrics are characterized by their fine microfibers, typically ranging from 0.1 to 15 micrometers in diameter. This small fiber diameter contributes to the high filtration efficiency of the fabric, enabling it to capture even the smallest particles, including bacteria and viruses.

2. High Filtration Efficiency: The BFE99 rating indicates that the fabric can filter out at least 99% of bacteria and other particulates. This high level of filtration efficiency is essential for medical applications where preventing the spread of pathogens is critical. The combination of fine fibers and high filtration capability ensures that melt blown nonwoven fabric meets stringent medical standards.

3. Breathability and Comfort: Despite its dense fiber structure, melt blown nonwoven fabric remains lightweight and breathable. This balance between filtration efficiency and breathability is crucial for medical masks and other protective gear, ensuring that they provide effective protection without causing discomfort to the wearer.

4. Strength and Durability: Melt blown nonwoven fabric possesses moderate strength due to mechanical entanglement and frictional forces between the fibers. This strength, combined with its other properties, makes it suitable for various demanding applications, including medical environments where reliability is paramount.

1. Polymer Selection: Polypropylene is the primary polymer used in the production of melt blown nonwoven fabric due to its favorable properties, such as low melting point and ease of processing. Other polymers like polyethylene and polyester can also be used depending on specific application requirements.

2. Extrusion and Blowing: The production process involves melting the polymer and extruding it through fine nozzles surrounded by high-speed blowing gas. This process creates ultra-fine microfibers, which are collected on a conveyor belt to form a nonwoven web. The randomness of the fiber orientation and the small pore size of the web are critical for achieving high filtration efficiency.

3. Web Formation and Collection: The collected fibers form a web with a uniform distribution, which is essential for maintaining consistent filtration performance. The web’s properties, such as basis weight and fiber diameter, can be controlled by adjusting the production parameters, ensuring that the final product meets specific requirements.

1. Medical Masks: One of the primary applications of BFE99 melt blown nonwoven fabric is in the production of medical masks, including N95 and surgical masks. These masks must provide high levels of protection against airborne particles and pathogens, and melt blown fabric’s superior filtration efficiency makes it the material of choice for these critical protective devices.

2. Surgical Gowns and Drapes: Melt blown nonwoven fabric is also used in the manufacture of disposable surgical gowns and drapes. These products need to create a barrier against pathogens while being comfortable for the wearer. The fabric’s breathability and lightweight nature ensure that these medical garments meet both safety and comfort standards.

3. Sterilization Wraps: In addition to protective clothing, melt blown nonwoven fabric is used for sterilization wraps, which are essential in maintaining sterile conditions during medical procedures. These wraps prevent the ingress of contaminants, ensuring the safety and sterility of surgical instruments and other critical equipment.

While medical applications are a significant focus, the versatility of melt blown nonwoven fabric extends to other fields:

1. Air and Liquid Filtration: Melt blown nonwoven fabric’s high filtration efficiency makes it suitable for air and liquid filtration systems. In HVAC systems, the fabric is used to filter out dust, pollen, and other airborne particles, maintaining clean indoor air quality. In water filtration systems, it removes impurities, ensuring the provision of safe and clean water.

2. Industrial Applications: In industrial settings, melt blown nonwoven fabric is employed in the production of oil sorbents and other filtration products. Its ability to absorb and retain large amounts of oil makes it crucial for managing spills and leaks, protecting the environment, and maintaining operational efficiency.

3. Hygiene Products: The absorbent properties of melt blown nonwoven fabric make it suitable for hygiene products such as diapers and feminine hygiene items. The fabric’s ability to manage liquids effectively ensures comfort and protection for users, making it an ideal choice for these applications.

The future of melt blown nonwoven fabric looks promising, with ongoing research and development aimed at enhancing its properties and expanding its applications. Innovations in polymer science and processing technology are expected to produce fabrics with even higher filtration efficiencies and improved performance characteristics. Additionally, the push towards sustainability is likely to lead to the development of more eco-friendly melt blown fabrics, further broadening their appeal and utility

BFE99 melt blown nonwoven fabric rolls are indispensable in the medical and filtration industries due to their superior filtration efficiency, breathability, and versatility. As the demand for high-quality protective equipment continues to rise, melt blown fabric will remain a critical component in ensuring health, safety, and environmental protection across various sectors. The combination of advanced production processes, stringent quality control, and innovative material science ensures that melt blown nonwoven fabric will continue to play a pivotal role in safeguarding public health.

In summary, the melt blown process has revolutionized the production of nonwoven fabrics, providing materials with exceptional filtration capabilities and a wide range of applications. The ongoing advancements in technology and sustainability efforts will continue to drive the development of melt blown fabrics, ensuring their relevance and importance in various industries for years to come.

Our robust production capacity and dedicated R&D team are geared towards saving your time, allowing you to seize the selling season. With six production lines dedicated to P.P. nonwoven fabric, our monthly output reaches an impressive 1300 tons.

Our sales team is well-versed in international trade, regularly participating in numerous domestic and international trade shows. Additionally, we leverage various online networking platforms to expand our presence and reach in the global market.

Ensuring a steady supply of raw materials, we commit to offering consistently stable pricing. This practice not only guarantees the mutual benefit of both parties involved but also serves as a risk-mitigation strategy in the dynamic landscape of nonwoven fabric trade. Our focus on securing ample raw material reserves empowers us to maintain pricing stability, fostering a reliable and enduring partnership that prioritizes mutual success and minimizes uncertainties associated with trade in this industry.

We boast a comprehensive quality management system alongside highly competitive pricing. Over 95% of our products, tailored to diverse fields, are exported to 30+ countries, meeting their specific requirements. Additionally, we have forged strong business partnerships with renowned global brands.

The OEKO-TEX® Standard 100 is an autonomous testing and certification protocol that covers textile raw materials, intermediates, and final products throughout their production stages. It encompasses various items eligible for certification, including clothing of all kinds, household textiles, bed linens, terry cloth items, textile toys, and more.

Find the more non-woven fabrics from our factory with free custom services at cheapest price.